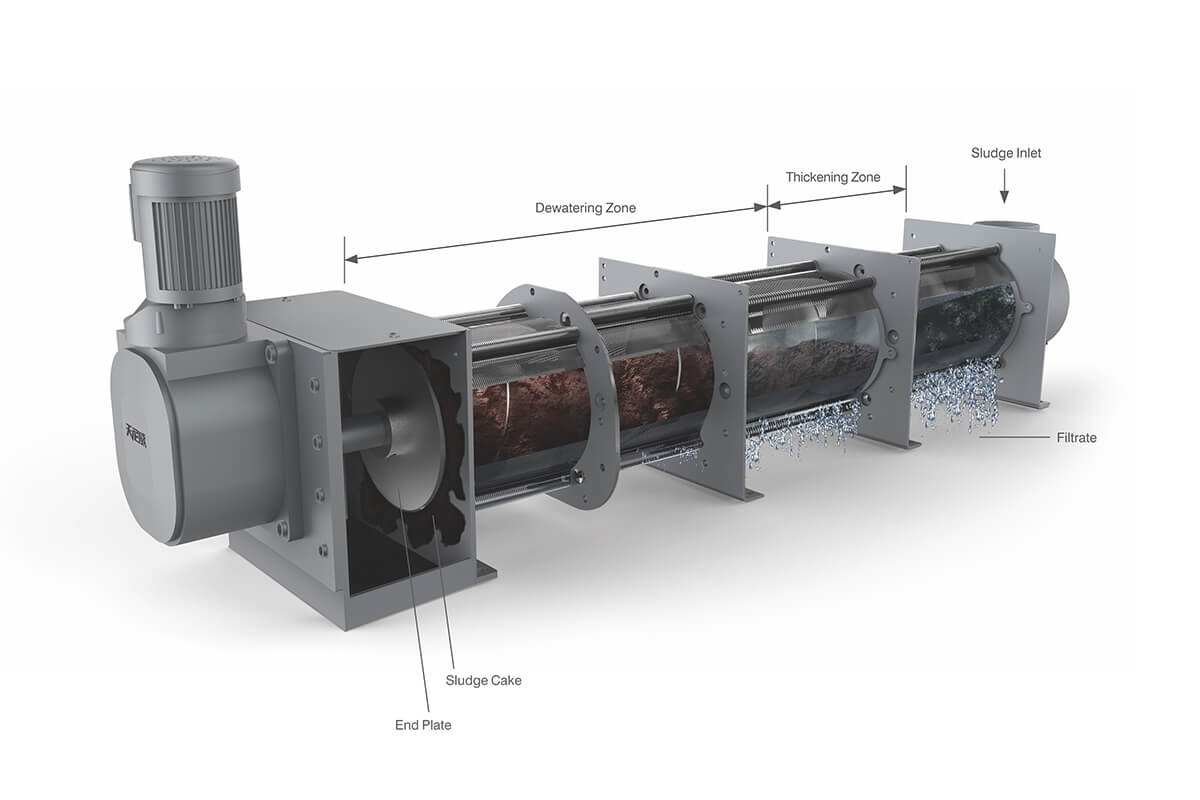

Screw sludge press structure

The screw sludge press, as an efficient sludge treatment equipment, plays an important role in many fields due to its unique structural design.

The screw sludge press is mainly composed of a screw shaft, dynamic and static rings, a driving device, and a filtrate collection tank. The spiral shaft is the core component of the machine, with special spiral blades designed on its surface to push the sludge forward during rotation. The dynamic and static rings are arranged in a staggered manner, forming a unique filtering space. When sludge enters this space, water can be effectively squeezed out.

The driving device provides power for the rotation of the spiral shaft, ensuring the stable progress of the entire dehydration process. The filtrate collection tank is responsible for collecting the filtrate squeezed out from the sludge for subsequent treatment.

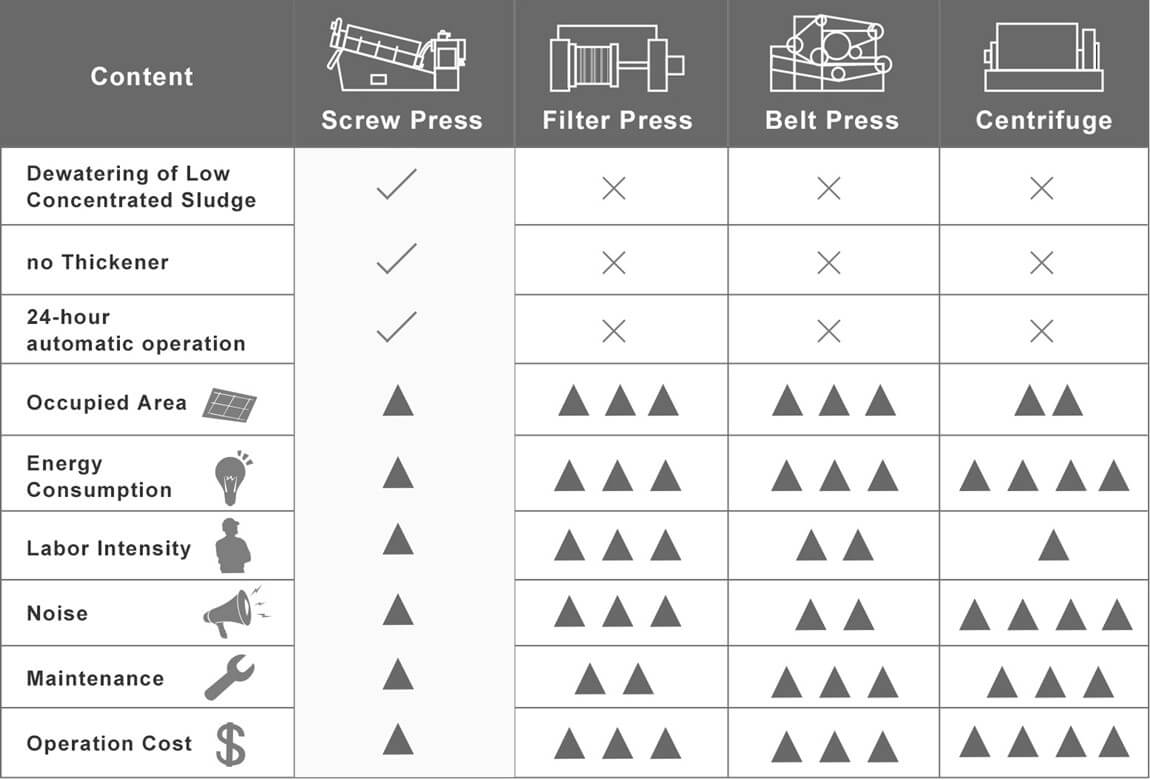

This structural design has many advantages. Firstly, it has a high dewatering efficiency, which can quickly separate the moisture in the sludge and reduce its moisture content. Secondly, its compact structure and small footprint make it suitable for various site conditions. The screw sludge press runs stably, has low noise, and is easy to maintain and upkeep.

In practical applications, screw sludge press can be widely used in fields such as sewage treatment plants and industrial wastewater treatment. It can effectively treat various types of sludge, contributing to environmental protection and resource recycling.

In summary, the structural design of the screw sludge press is scientifically reasonable, and its unique advantages make it an important equipment in the field of sludge dewatering treatment. With the continuous advancement and innovation of technology, we believe that sludge dewatering machines will play a greater role in the future, creating a cleaner and better environment for us.

PRE : Screw filter press: an efficient tool for industrial solid-liquid separation